Case Studies

Alternative Energy

Electrochaea

IMPACT helped develop a “power-to-gas” technology based on a biologically catalyzed, electrolytic methane formation process that converts low-cost and stranded electricity into pipeline-grade renewable gas for direct injection into the existing natural gas grid.

GlucanBio

IMPACT provides expertise in process development and scale-up to a start-up with a proprietary catalytic process for the production of furan derivatives from C5 and C6 sugars. The technology enables higher efficiency at anticipated lower capital and operating costs than competitive processes.

Solid Energies

IMPACT provides expertise to an innovative pyrolysis waste to energy technology, analyzing the reaction processes and providing an external opinion for investors on the viability of the system and its ability to be scaled up.

Chemicals

BOC Gases

IMPACT manages the commissioning, automation, and operations support for a $40M green field ultra high purity microelectronics gas purification and packaging plant ten times larger than any previous facilities.

Emerald Kalama Chemicals

IMPACT helped convert a specialty chemical batch manufacturing process into a continuous process. Bench scale testing of the continuous process was performed at the IMPACT Development Center.

General Chemicals

IMPACT helped a leading supplier of waste water flocculant (ferric sulfate) de-bottleneck their manufacturing plant and reduce process cycle times by over 25%

Reheis Chemicals

IMPACT developed a capacity and utilization model for a specialty chemical manufacturer producing over 80 different products to improve plant profitability and prioritize plant expansion plans.

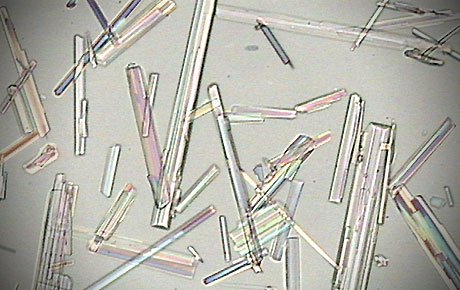

Strem Chemicals

When capacity for a sublimed metal product exceeded bench scale capacity, IMPACT designed, constructed, and implemented a large scale sublimation system which successfully met new production needs.

Voltaix

IMPACT developed and scaled-up a new organosilane process from bench scale to commercial production while simultaneously managing the construction and start-up of a manufacturing facility for the new chemical.

Medical Devices & Diagnostics

Guava Technologies

IMPACT developed and wrote validation packages for a line of cytometry equipment (PCA, EasyCyte, EasyCyte mini, and ViaCount Assay) including IQ/OQ and PQ.

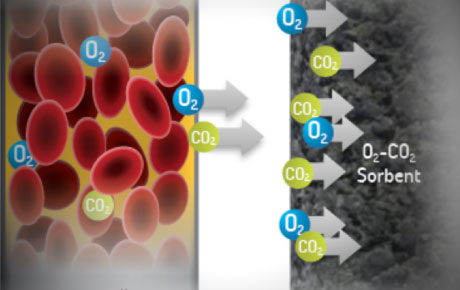

New Health Sciences

IMPACT helped with the initial modeling and design of a new packed red blood cell de-oxygenation technology, HemaNext®, for extending the storage life of the world blood supply.

OptMED

IMPACT helped develop and scale-up a process for producing an innovative surgical sealant technology based on isocyanoacrylic chemistry. The technology is used for skin closure from wounds or surgery.

U. S. Genomics

IMPACT utilized our knowledge in particle technology, separations, and process/product design experience to develop an air sampling device for bio-weapons sensing under a HSARPA grant.

Metallurgical Processes

Akar Kvaerner

IMPACT’s combined expertise in metallurgical injection systems and computational modeling increases a triple concentric injection lances life cycle by over 2 times enabling positive economic performance.

Crystal Systems

IMPACT provided thermal modeling of melting and solidification in sapphire refining furnaces to improve overall process efficiency and product quality.

GT Advanced Materials

IMPACT improved process reliability and safety for directional crystallization reactors for photovoltaic grade silicon via CFD modeling, safety analysis (HAZOP), new intrinsically safe designs, and safer operational procedures following an FMEA analysis.

Molten Metal Technology

Several members of the IMPACT team worked for Molten Metal Technology (MMT) in the 1990’s, a company that commercialized waste recycling via molten metal reactors, or solvation within liquid metal baths of varying composition (Fe, Cu, Sn, etc.) and controlled chemistry. The technology was applied to various hazardous wastes including radioactive spent ion exchange resins, chlorinated wastes, incinerator fly ash, and auto shredder residue.

Ze-Gen

IMPACT helped re-strategize and execute the development, scale-up and launch of a commercial molten metal recycling technology.

Pharmaceuticals & Biopharmaceuticals

Altus Pharmaceuticals

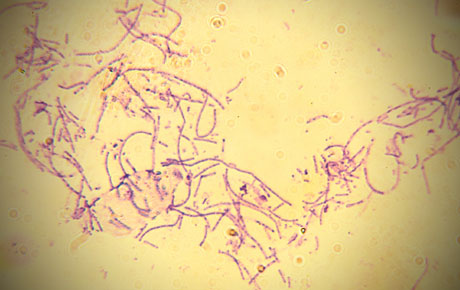

For over 6 years, IMPACT helped develop, scale-up and commercialize large-molecule crystallization processes. Our efforts included development of processes and design of custom equipment for crystallization, recovery, and post-processing of various therapeutic proteins including enzymes and hormones.

Epic Therapeutics

IMPACT utilized particle nucleation models, computational fluid dynamics (CFD) and complex suspension rheology expertise to develop both batch and continuous precipitated microsphere processes for large-molecule drugs.

FTS Systems

IMPACT helped a troubled new lyophilization product launch by using failure modes and effects analysis (FMEA) to direct and prioritize engineering activities to overcome performance and reliability issues.

GlycoGenesys

IMPACT helped a start-up company overcome scale-up and process reliability issues of a pectin-based oncology drug during technology transfer to a contract manufacturing organization (CMO).

Infimed Therapeutics

IMPACT helped understand both manufacturing and bioavailability/biocompatibility problems with a PEG-based microsphere technology for rhGH and developed solutions.

Millipore, GE, and Pall

When three of the world’s largest biopharma filtration companies needed expertise on centrifugation to gain a competitive advantage, they all came to IMPACT for help.

Natrix Separations

IMPACT is helping Natrix to productize its innovative, single-use, HD-membrane-based chromatography platform for biomolecule purification.

PneumaticScaleAngelus

IMPACT conceived, developed, and in partnership commercialized the world’s first single-use process centrifuge for bio-manufacturing, UniFuge®.

Stryker Biotech

IMPACT scales-down a particle reaction/washing process to study mixing and shear effects on the product to insure a successful manufacturing process start-up.

Takeda Pharmaceuticals

IMPACT provided third party due diligence expertise in microsphere process development and production to help client qualify and validate potential technology relationships with microsphere-based technology companies.

Transform Pharmaceuticals

IMPACT helped with the process scale-up of a drug formulation prior to technology transfer to a contract manufacturing organization, overcoming a number of complicating mixing and filtration phenomena

Xanthus Pharmaceuticals

IMPACT acquires and modifies a lab-scale lyophilizer to accommodate cycle development of a new cytotoxic cancer drug candidate.